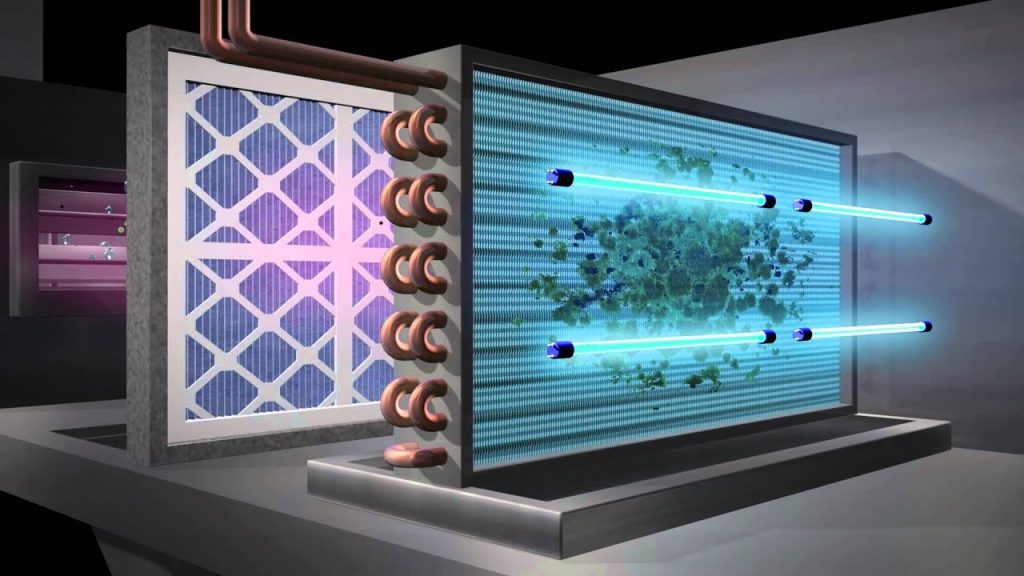

Integrating UV-C light into HVAC systems effectively maintains cleanliness, boosts airflow, and enhances overall system performance. Ultraviolet germicidal irradiation (UVGI), particularly at 253.7 nanometers, has been incorporated into HVAC systems since the mid-1990s.

This technology helps prevent the accumulation of organic materials like mold, bacteria, and other microorganisms on components such as cooling coils and drain pans. To fully leverage the advantages of UV-C technology in HVAC systems, it’s crucial to accurately size the UV-C light for the specific application. This guide will delve into the process of correctly sizing UV-C light for HVAC systems to ensure optimal performance and energy efficiency

Why Use UV-C in HVAC Systems?

Key Factors for Sizing UV-C Light in HVAC Systems

1. Essential UV-C Energy

First, determine the UV-C energy needed for effective cleaning. Industry standards, like those from ASHRAE, provide clear guidelines for UV-C use in HVAC systems, especially on cooling coils. The 2015 ASHRAE Handbook – HVAC Applications suggests a UV-C dosage of 50 to 100 µW/cm² for cooling coil surfaces. This level must be achieved across the entire coil, even in hard-to-reach spots like plenum corners.

2. Lamp Output and Placement

3. Boosting UV-C Performance with Reflectivity

4. Simplified Sizing Formula: Watts per Square Foot

5. Choosing the Right UV-C Lamp Type

Two main UV-C lamp types are used in HVAC systems: single-ended and double-ended.

Installation Considerations

When installing UV-C lights in an HVAC system, it’s crucial to position the lamps correctly for peak effectiveness. Typically, placing the lamps twelve inches from the coil is ideal for most systems, although this can vary with different configurations. Alongside proper positioning, it’s important that the UV-C system features controls for safe operation and easy maintenance. Safety measures like door interlock switches can automatically turn off the UV-C lamps when access doors are opened. Additionally, incorporating lamp failure indicators and self-powered current sensors can alert facility managers to any lamp outages, minimizing the need for manual checks

Maintenance and Lamp Replacement

To maintain consistent performance, UV-C lamps should be swapped out annually. Over time, their effectiveness declines, even if they still appear to be working. Regular maintenance and timely replacement are crucial to keeping the system’s cleaning capabilities intact and ensuring the HVAC system runs optimally.

Conclusion

Selecting the right size for UV-C lighting in HVAC systems is vital for maximizing the cleaning and maintenance of key components like cooling coils. By adhering to ASHRAE guidelines for UV-C dosage and employing the straightforward 7.5 watts per square foot sizing approach, HVAC experts can design and install UV-C setups that boost energy efficiency, enhance indoor air quality, and lower operating costs. With UV-C technology, HVAC systems can function at their designed capacity, offering cleaner air and improved efficiency for the long term.

UV Light Size Calculator for HVAC

Note: Adjust airflow and temperature values for accurate results.