Have you ever been curious about what are chillers in HVAC? Chillers play a crucial role in many commercial operations, offering essential cooling and ventilation services across various industries such as construction and industrial manufacturing.

These systems, while complex and demanding professional installation and maintenance, are more understandable once you grasp the fundamentals of their operation. Having this knowledge can empower customers to make more informed decisions when selecting a chiller system tailored to their specific requirements. In this blog, we will delve into the key basics of how an HVAC chiller system functions.

What is a chiller, and what are its main components?

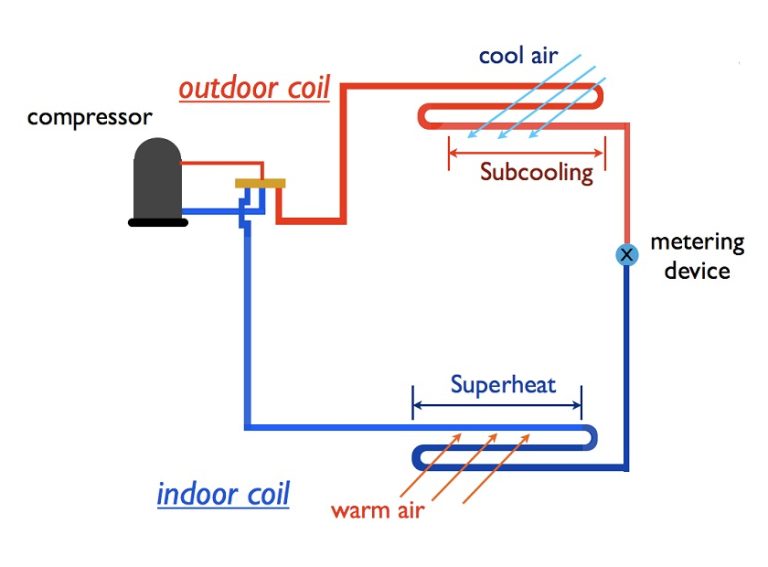

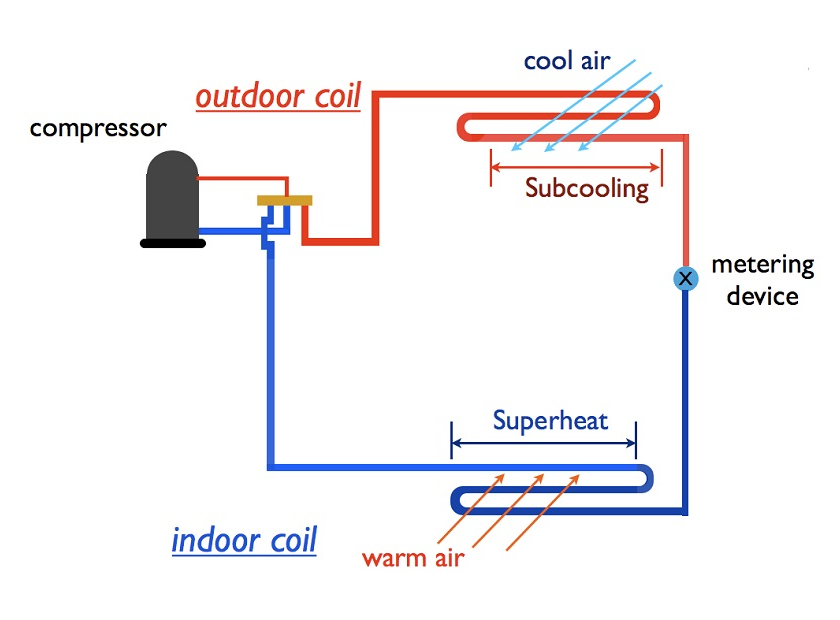

A chiller plays an essential role in various industrial processes by offering a consistent supply of cool water, crucial for maintaining the optimal temperature of machinery and equipment. By extracting heat from water circulated through its system and releasing it into the surrounding environment, a chiller ensures efficient temperature regulation. The primary components of a chiller system include the compressor, evaporator, condenser, and expansion valve..

The compressor’s function is to compress the refrigerant, elevating its temperature and pressure. Next, the evaporator absorbs heat as the refrigerant passes through the chilled water, transforming it into a gaseous state. This gas is then directed to the condenser, where it is cooled back into a liquid form. Finally, the liquid is sent to the expansion valve, which decreases its pressure before it returns to the evaporator, starting the cycle anew. Understanding these essential components helps maintain the chiller’s efficiency while preventing expensive repairs and breakdowns.

How does the chilling process work in a closed-loop system?

In a closed-loop system, the chilling process operates by circulating refrigerant through a network of pipes and heat exchangers, effectively drawing heat away from the product being cooled. The refrigerant, which is a low-temperature fluid, has a high capacity for heat absorption as it flows through the system.

As it navigates through the pipes, the refrigerant meets heat exchangers interacting with the product, facilitating the transfer of heat from the product to the refrigerant. The compressor then compresses the refrigerant, raising its temperature and pressure. Subsequently, the high-pressure, high-temperature refrigerant is cooled and reverted to a low-pressure liquid through the condenser. This liquid is circulated back through the network of pipes and heat exchangers, perpetuating the chilling process. This closed-loop mechanism is highly efficient, making it a favored option for various cooling applications.

Basic Chiller Components

The main components of a chiller system are as follows:

- Condenser

- Compressor

- Evaporator

- Expansion valves

- Power unit

- Control unit

- Water boxes

Condenser

A chiller’s condenser plays a key role in removing heat from the refrigerant as it circulates within the system. For water-cooled types, this process involves moving water between the condenser and a cooling tower. In air-cooled versions, cool air is blown over the condenser pipes to achieve the same effect.

Compressor

The compressor is integral to the operation of any chiller. It creates the necessary pressure differential to propel refrigerant through the chiller, enabling effective cooling. Compressors come in various forms, with centrifugal, screw, and reciprocating types being the most common.

Evaporators

Positioned between the expansion valve and the condenser, evaporators extract heat from the process fluid and into the refrigerant. Depending on the chiller’s design, this heat is then transferred to a cooling tower or managed with air-cooling methods.

Thermal Expansion Valves

Thermal expansion valves, situated between the compressor and evaporator, allow the refrigerant to expand. This expansion reduces pressure and enhances the heat removal capability of the evaporator.

Power Unit

A chiller’s power unit is crucial for managing the electrical flow throughout the system. It typically includes components like starters, power monitoring panels, and circuit breakers, ensuring steady and efficient energy use.

Control Panels

Control panels are vital for overseeing the cooling process. They feature various sensors, alarms, and display screens that enable operators to fine-tune system settings to maintain optimal thermal conditions.

Water Boxes

Water boxes are either attached to the evaporator or the water-cooled condenser of the chiller system. Their function is to facilitate efficient water flow, contributing to the overall performance of the chiller.

Working Principles

Industrial chillers work based on the following principles of operation.

- Phase Change: When heated, a liquid coolant undergoes a phase change into a gas, and when the gaseous coolant is supercooled, it condenses back into a liquid.

- Heat Flow: Heat energy always flows from an area of high concentration to an area of lower concentration.

- Boiling Point: Reducing the pressure over a liquid decreases its boiling point, and increasing the pressure increases its boiling point.

Types of Industrial Chillers

Today, the main varieties of chillers include air-cooled, water-cooled, and absorption chillers. We will also briefly discuss cooling towers, which can serve as an alternative or complementary cooling system, along with specialized chillers like glycol and centrifugal models. Choosing the appropriate chiller for your needs can lead to cost savings, reduced downtime, and enhanced operational efficiency.

Water-Cooled Chillers

Water-cooled chillers utilize water from an external cooling tower to dissipate heat from a gaseous refrigerant in the condenser. This process results in the refrigerant undergoing a phase change into a liquid state.

Air-Cooled Chillers

Unlike water-cooled systems, air-cooled chillers use ambient air to expel heat from the refrigerant in the condenser. For more information, explore the differences between air-cooled and water-cooled chillers.

Vapor Compressor Chillers

These chillers employ refrigerants to cool fluids and spaces. A compressor acts as the driving force, circulating the refrigerant throughout the system.

Vapor Absorption Chillers

Vapor absorption chillers operate without a compressor. Instead, they rely on a heat source, such as solar energy or waste heat, to propel the coolant through the system.

How does an absorption chiller work?

The process begins with liquid coolant in an evaporator, which transforms it into a gas. This gaseous coolant is then absorbed by a concentrated absorbent (e.g., Lithium Bromide or Ammonia) provided by a generator. The diluted solution absorbs the coolant, while the cooling water absorbs the heat. The mixture is then sent through a heat exchanger to the generator, where it is heated, causing the coolant to vaporize and be sent out for cooling once more. The absorbent is recycled for continued use.

Glycol Chillers

Glycol chillers are unique models that use propylene glycol, an antifreeze, within the system. They are commonly used in food-grade applications, such as alcohol production and brewery chilling systems.

How does a glycol chiller work?

Glycol chillers operate similarly to standard chillers, using the same basic principles.

Centrifugal Chillers

Centrifugal chillers feature the typical setup of an evaporator, compressor, condenser, and expansion device, but they also include rotating impellers. These impellers compress the refrigerant and circulate it through the system, making them particularly useful for medium to large-scale cooling operations, ranging from 150 to 6000 tons of refrigeration

Uses of Industrial Chillers

Industrial chiller systems play a vital role in cooling operations across various industries. Here are some of their most common applications:

- Food Processing – Precision in temperature control is crucial in food production and processing. Industrial chillers are extensively used in these operations. For example, winery chillers help maintain the right temperature during wine fermentation and storage. Similarly, in bakeries, chillers manage mixer cooling, potable water cooling, and the cooling of yeast tanks, all essential to bakery operations.

- Metal Finishing – Metal finishing processes like electroplating or electroless plating demand strict temperature control. These processes often require very high temperatures to bond metals, making excess heat removal critical. Industries might use metal-finishing chillers to cool the anodizing liquid through a heat exchanger or employ glycol/water to lower the tank’s temperature.

- Injection Molding – As a mass-production method for plastic parts, injection molding requires precise temperature management to prevent issues like warping, cracks, and internal stresses in products. Injection molding chillers provide supercooled fluid streams to optimally cool molds, ensuring high-quality output.

- Space Cooling – In manufacturing environments where heavy machinery generates substantial heat, chillers help maintain comfortable temperatures in office spaces and work areas. They also offer cost savings by eliminating the need for separate HVAC systems.

Determining the Right Size of Chiller for Your Needs

Selecting the correct chiller size is vital for efficient, cost-effective cooling of processes, equipment, and spaces. Utilize online tools to quickly determine your ideal chiller capacity, tonnage, and size.

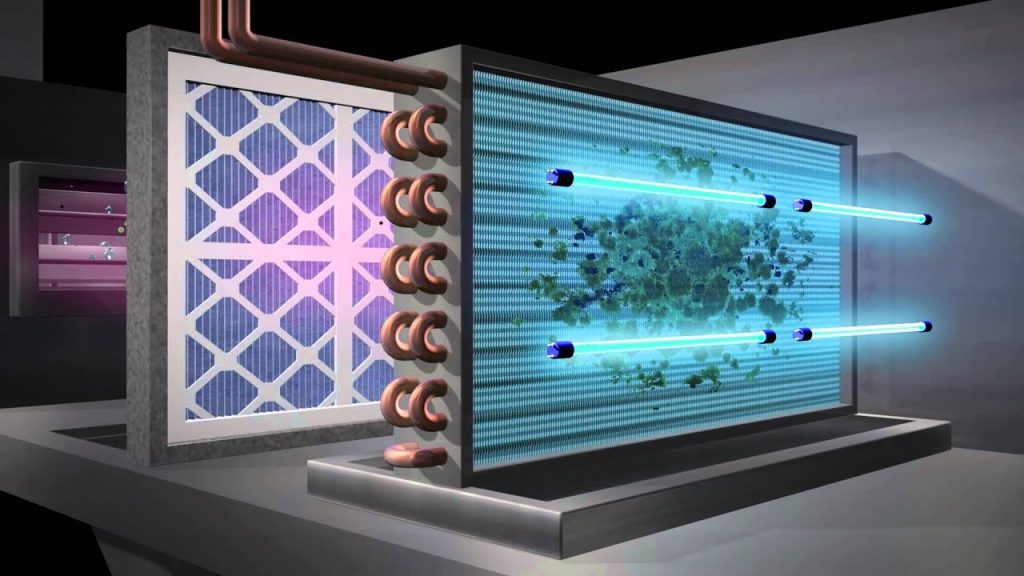

Getting The Most Out of Your Chiller

Though installation and operation of chiller systems can be costly, maximizing their efficiency is key to minimizing additional expenses. Regular maintenance, including inspections and cleaning of condenser coils and maintenance of condenser water and refrigerant, is essential to prevent expensive repairs down the line.

FAQs

How to Maintain a Chiller for Optimal Performance

Chillers play a crucial role in many industrial processes by removing heat and keeping operations running smoothly. For your chiller to operate efficiently, regular upkeep is crucial. Key maintenance steps include inspecting and cleaning critical parts like evaporator and condenser coils, monitoring refrigerant levels, and replacing any worn components.

What’s the Difference Between a Chiller and a Chilled Water System?

Chillers use a refrigeration cycle to transfer heat from water to either the surrounding air or another cooling medium, like water. Chilled water systems, on the other hand, circulate cooled water through pipes and coils to absorb heat from a building or facility’s air. The chilled water returns to the chiller for re-cooling, creating a continuous cycle. These systems efficiently cool large areas and are widely used in commercial and industrial settings. Think of a chiller as a water cooler—it cools and dispenses water. Meanwhile, the chilled water system acts like the cups and straws, holding and distributing the chilled water where needed.