You’ll find Packaged Terminal Air Conditioners, or PTACs, built into walls across many hotels and apartment buildings. These all-in-one heating and cooling units let people control the temperature in their own rooms. Building owners love them because they can cool and heat spaces without needing complex ductwork, and you’ll spot them everywhere from office buildings to retirement homes. They’re pretty handy since each room gets its own unit that residents can adjust to their liking.

Technical Overview

Basic Specifications

Specification | Typical Range |

Cooling Capacity | 7,000 – 15,000 BTU/h |

Heating Capacity | 6,000 – 17,000 BTU/h |

Voltage Requirements | 208/230V, 265V, 277V |

Amperage | 15-30 Amps |

EER Rating | 9.0 – 13.0 |

Dimensions (WxHxD) | 42″ x 16″ x 24″ (standard) |

Weight | 80-120 lbs |

Airflow Rate | 250-400 CFM |

Sound Level | 45-75 dB |

Operating Principles

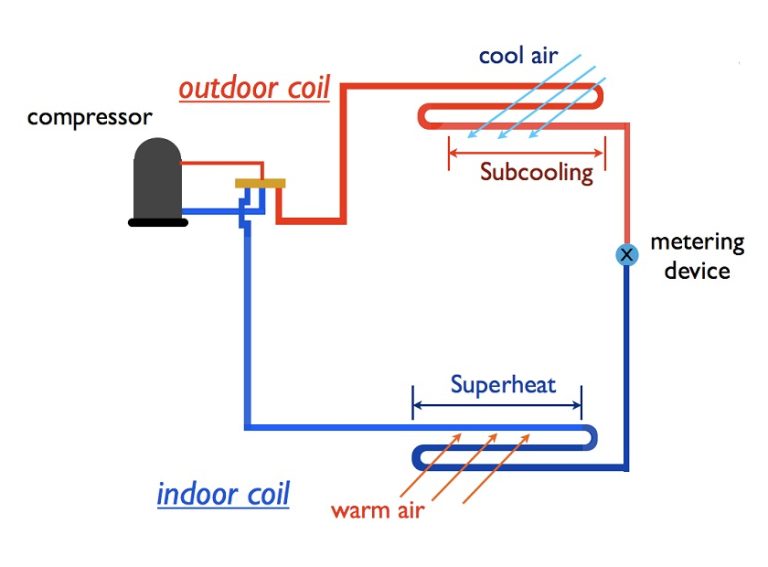

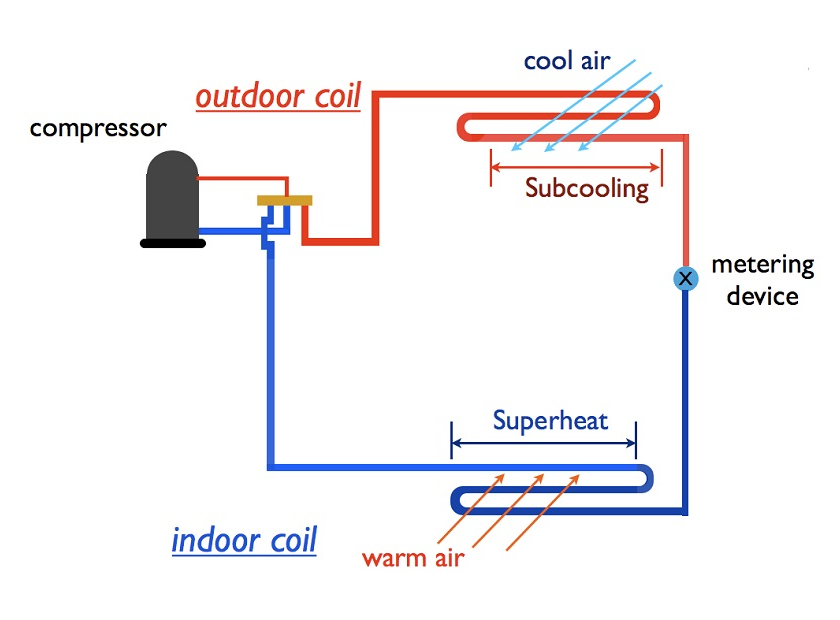

PTACs operate using the vapor-compression refrigeration cycle:

- Compression

- Condensation

- Expansion

- Evaporation

Components and Operation

Major Components

- Compressor

- Type: Rotary or reciprocating

- Capacity: 0.5-1.5 tons

- Operating pressure: 150-450 PSI

- Refrigerant types: R-410A (modern units)

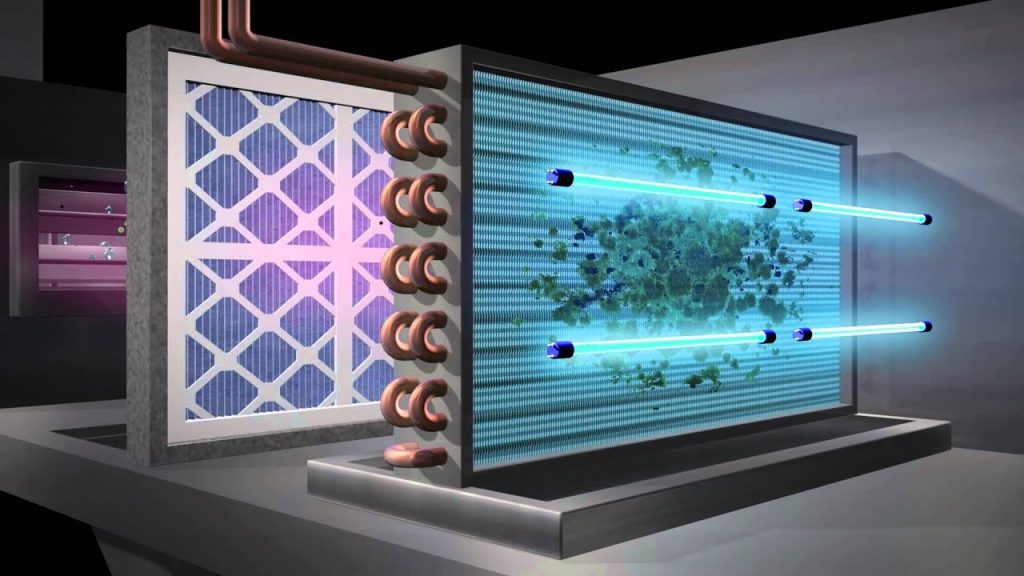

- Heat Exchangers

- Condenser coil

- Material: Copper tubes with aluminum fins

- Fin density: 12-14 fins per inch

- Evaporator coil

- Material: Copper tubes with aluminum fins

- Fin density: 14-16 fins per inch

- Condenser coil

- Fans and Motors

- Indoor fan

- Type: Centrifugal

- Speed settings: 3-4

- Airflow: 250-400 CFM

- Outdoor fan

- Type: Propeller

- Speed: Single or variable

- Airflow: 400-600 CFM

- Indoor fan

- Control Systems

- Digital thermostat

- Microprocessor control board

- Temperature sensors

- Fan speed control

- Mode selection

Refrigeration Cycle Details

Types of PTAC Units

By Heating Method

- Heat Pump Models

- Efficiency: 3.0-3.8 COP

- Operating range: 25°F to 85°F

- Reversing valve operation

- Defrost cycle details

- Electric Heat Models

- Heating capacity: 2-5 kW

- Element types: Nichrome wire

- Safety features: Thermal cutoff

- Control methods

- Hydronic Heat Models

- Hot water coil specifications

- Flow rates: 1-3 GPM

- Temperature range: 120-180°F

- Pump requirements

By Cooling Capacity

Size Category | BTU/h Range | Room Size (sq ft) | Typical Application |

Small | 7,000-9,000 | 250-400 | Guest rooms |

Medium | 9,100-12,000 | 400-550 | Small offices |

Large | 12,100-15,000 | 550-700 | Conference rooms |

Sizing and Selection

Load Calculation Factors

- Room Characteristics

- Square footage

- Ceiling height

- Window area

- Wall insulation (R-value)

- Environmental Factors

- Geographic location

- Solar exposure

- Outdoor design temperatures

- Humidity levels

Sizing Formula

$$\text{Required BTU/h} = (\text{Room Volume} \times 20) + (\# \text{ of Windows} \times 1000) + (\# \text{ of Occupants} \times 400)$$

Installation Guidelines

Wall Sleeve Requirements

- Standard Dimensions

- Width: 42 inches

- Height: 16 inches

- Depth: 24 inches

- Installation Clearances

- Top: 6 inches

- Sides: 6 inches

- Front: 36 inches

- Rear (outdoor): 12 inches

Electrical Requirements

- Circuit Specifications

- Dedicated circuit required

- Wire gauge: 10-12 AWG

- Circuit breaker: 20-30 amp

- GFCI protection recommended

- Connection Types

- Hard-wired configuration

- Receptacle options

- Sub-base requirements

Drainage Systems

- Condensate Management

- Internal slope: 1/4 inch per foot

- Drain pan capacity: 1-2 gallons

- Overflow protection

- Secondary drain requirements

Maintenance and Troubleshooting

Preventive Maintenance Schedule

Component | Monthly | Quarterly | Annually |

Air Filter | Clean/Replace | Deep clean | Replace |

Coils | Visual check | Clean | Deep clean |

Drain Pan | Clean | Sanitize | Replace gaskets |

Fan Motors | Check operation | Lubricate | Test amperage |

Controls | Test operation | Calibrate | Replace batteries |

Common Issues and Solutions

- Insufficient Cooling

- Check refrigerant pressure

- Clean coils

- Verify fan operation

- Test compressor operation

- Unusual Noise

- Inspect fan bearings

- Check compressor mounts

- Verify panel fasteners

- Evaluate blower wheel

- Water Leaks

- Clear drain line

- Level unit

- Check seals

- Inspect drain pan

Diagnostic Procedures

- Electrical Testing

- Voltage measurements

- Amperage readings

- Continuity tests

- Control board diagnostics

- Mechanical Checks

- Pressure testing

- Airflow measurement

- Temperature differential

- Refrigerant charge

Energy Efficiency

Energy Saving Features

- Digital Controls

- Programmable schedules

- Occupancy sensors

- Temperature limits

- Energy management integration

- Performance Optimization

- Variable speed fans

- ECM motors

- Enhanced coil design

Smart defrost control

Energy Consumption Analysis

Cost Analysis

Initial Costs

- Equipment

- Base unit: $700-1,500

- Installation materials: $200-400

- Labor: $300-600

- Operating Costs

- Annual energy usage: 2,000-3,500 kWh

- Maintenance: $100-200/year

- Filter replacements: $30-50/year

Lifecycle Cost Comparison

System Type | Initial Cost | Annual Operating Cost | 10-Year Cost |

Standard PTAC | $1,200 | $400 | $5,200 |

High-Efficiency PTAC | $1,500 | $300 | $4,500 |

Central HVAC (per room) | $2,000 | $250 | $4,500 |

Applications

Commercial Applications

- Hospitality

- Hotels

- Motels

- Resorts

- Bed & breakfasts

- Healthcare

- Patient rooms

- Medical offices

- Nursing homes

- Rehabilitation centers

- Office Buildings

- Individual offices

- Conference rooms

- Break rooms

- Reception areas

Residential Applications

- Multi-Family Housing

- Apartments

- Condominiums

- Dormitories

- Senior living facilities

- Single-Family Additions

- Sunrooms

- Garage conversions

- Home offices

- Basement finishing

Building Code Requirements

International Building Code (IBC)

- Installation Requirements

- Structural support

- Fire ratings

- Access requirements

- Ventilation standards

- Safety Standards

- UL 484 compliance

- Electrical codes

- Seismic requirements

- Fire safety

Energy Codes

- ASHRAE 90.1

- Minimum efficiency requirements

- Control requirements

- Installation standards

- Testing procedures

- Local Requirements

- Climate zone specifications

- Energy efficiency standards

- Noise regulations

- Zoning requirements

Environmental Impact

Environmental Considerations

- Refrigerant Management

- Type: R-410A

- GWP (Global Warming Potential)

- Leakage prevention

- Recovery procedures

- Energy Conservation

- Peak load reduction

- Demand response capability

- Smart grid integration

- Energy Star compliance

Sustainability Features

- Materials

- Recyclable components

- Sustainable manufacturing

- Packaging reduction

- End-of-life disposal

- Operation

- Low-power modes

- Automated efficiency

- Smart controls

- Eco-friendly options

Frequently Asked Questions

Q: What's the typical lifespan of a PTAC unit?

A: With proper maintenance, PTAC units typically last 7-10 years in commercial applications and up to 15 years in residential settings.

Q: How often should the air filter be cleaned?

A: Air filters should be cleaned monthly and replaced every 3-6 months depending on usage and environmental conditions.

Q: Can PTACs be used for primary heating in cold climates?

A: Heat pump PTACs are effective down to about 25°F. Below that, auxiliary electric heat or alternative heating sources are recommended.

Q: What's the average cost to replace a PTAC unit?

A: Total replacement costs typically range from $1,000 to $2,500, including installation and materials.

Q: How loud are PTAC units?

A: Modern PTAC units operate between 45-75 decibels, comparable to normal conversation to moderate street noise.

Q: Can I install a PTAC unit myself?

A: While possible, professional installation is recommended due to electrical requirements and the need for proper wall sleeve installation.

Q: How much electricity does a PTAC unit use?

A: Average units consume 2,000-3,500 kWh annually, depending on usage patterns and climate.

Q: Are PTAC units energy efficient?

A: Modern PTACs can be quite efficient, with EER ratings ranging from 9.0 to 13.0, though efficiency varies by model and usage.

References

- ASHRAE Handbook – HVAC Systems and Equipment (2020)

- Air-Conditioning, Heating, and Refrigeration Institute (AHRI) Directory

- International Building Code (IBC) – Latest Edition

- Energy Star Program Requirements for PTACs

- Department of Energy – Building Technologies Office

- HVAC&R Research Journal, Volume 25, Issue 4

- Building Operating Management – PTAC Maintenance Guide

- Energy.gov – Room Air Conditioners Guide

- International Journal of Energy Research

- EPA Regulations on HVAC Systems

Note: Please verify all references and specifications as standards and regulations may vary by location and change over time.